Pneumatic Tube Systems Since 1967

Request Info

Pneumatic Tube Systems Since 1967

Request Info

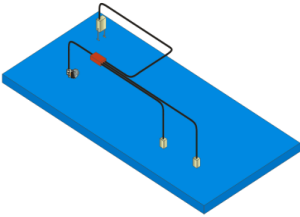

The Semi-Automatic Pneumatic Tube System is a hybrid of the Automatic and Point-to-Point systems. This system is generally used in facilities that need a central location that receives all carriers as the final destination or as a screening point before forwarding the carrier to another location.

Labs and manufacturing facilities tend to purchase these systems so that many different locations can send samples to one main testing area for analysis. This system does not allow sending locations (substations) to send directly to each other. Each substation sends carriers to the main station (master) first, which then forwards the transaction on to the next place.

The Semi-Automatic System currently uses an Automatic station as the master station and uses Zip Basic stations as the substations. In the future, if the facility wishes to upgrade to an automatic station, they already have much of the basic equipment needed to do so.

Our Semi-Automatic System is designed to have one master station and as many substations as your facility requires. These systems have a central location (master station) that can send and receive to other locations (substations). The substations can only send to the master station and not to each other.

This setup is ideal for facilities that have many locations that need to send to one central location. Instead of using point-to-point systems and having to add one station per system to the central location, the semi-automatic system provides that same functionality while reducing space requirements for the pneumatic tube system. Examples of facilities that use semi-automatic systems include manufacturing plants, casinos, and even supermarkets that have requirements for regular money deposits to a safe location.

Recommended Carriers for this system: Bankmark and Adanac.

Work environments that currently use this system:

Healthcare

Samples, specimens, blood vials, IV bags, and more.

Office Buildings

Documents, forms, receipts, and more.